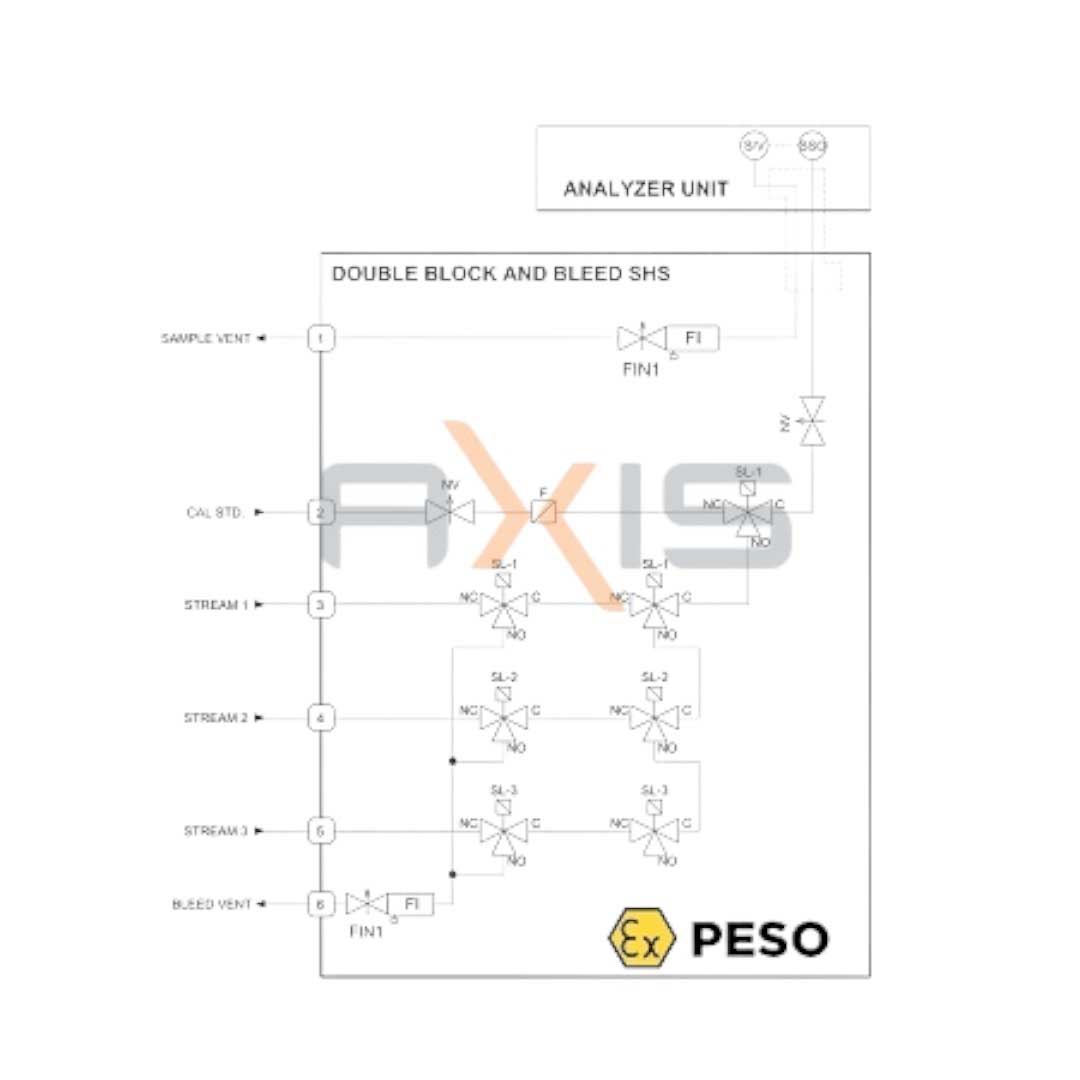

Double Block And Bleed System

The Double Block and Bleed System prevents cross-stream contamination in multi-stream sample systems by using a design that directs sample flow through two valves while other streams are double blocked. It handles both gas and liquid applications, features solenoid or air-operated switching valves, and can be equipped with fine filters and rotameters. This system is reliable, precise, and suitable for critical process services, meeting CCOE and ATEX certification standards.

Description:

ASPL Double block and bleed is a special design to ensures that cross-stream contamination does not occur in multi-stream sample systems which are caused due to is leakages from switching valves and areas of unpurged tubing common to more than one stream.

As can be seen below diagram this design allows sample flow from the selected stream to pass through two valves enroot to the sample/calibration valve. The other streams are double blocked with two valves and leakages from valves at low pressure to escape out the bleed vent.

Hence here the purpose is now served by double block and bleeds valve, firstly it will prevent contamination in all the streams and remove the trap gas/ liquid by means of the given bleed vent/drain.

The solution can be provided for gases and liquid applications. In case of liquid contamination shall be connected to drain. Switching valves shall be provided Electric operated solenoid valve or air operated valve.

Multi-stream sample selection and calibration switching command shall be given by the analyzer unit/control unit. Sample fine filter and rotameters can be added to make it a complete sample system as per customer-specific requirements. This improves the reliability of the system where precise measurement is highly required.

| Specification | Details |

|---|---|

| Features |

|

| Advantages |

|

| Specification | Refer to the datasheet for more details |

Optimize Your Industrial Efficiency Today

Unlock unparalleled productivity and efficiency with Third Eye Automation’s cutting-edge solutions. Contact us to learn more.

"*" indicates required fields